Thermal Printer Mechanisms

Compact, reliable low voltage thermal printer mechanisms are the answer for portable printing applications, offering low power consumption to enable long battery life. The innovative small footprint designs free up critical design real estate.

New low voltage LTPD and CAPD series thermal printer mechanisms tackle the challenges of designing smaller, faster, more reliable mobile devices. These new mechanisms deliver exceptional value with dramatic advances in design flexibility, reliability and print performance.

CAPM series direct thermal printer mechanisms are ideal for high performance, heavy-duty embedded printing applications. 300 mm/second print speed means exceptional performance, for a better user experience. Service life ratings of up to 200 km printing and 2 million cuts ensure long-life, trouble-free operation. Extended operating temperature range and thick paper support provide additional application options such as outdoor ticket printing. Units are available in both EZ-OP paper operation and auto-loading designs.

Applications

Thermal printers and thermal print mechanisms are small, light and consume little power, making them ideal for portable and retail applications. Commercial applications of thermal printers include petrol station pump receipts, information kiosks, point-of-sale systems, voucher printers, ticket machines, hospital cardiac monitors and more.

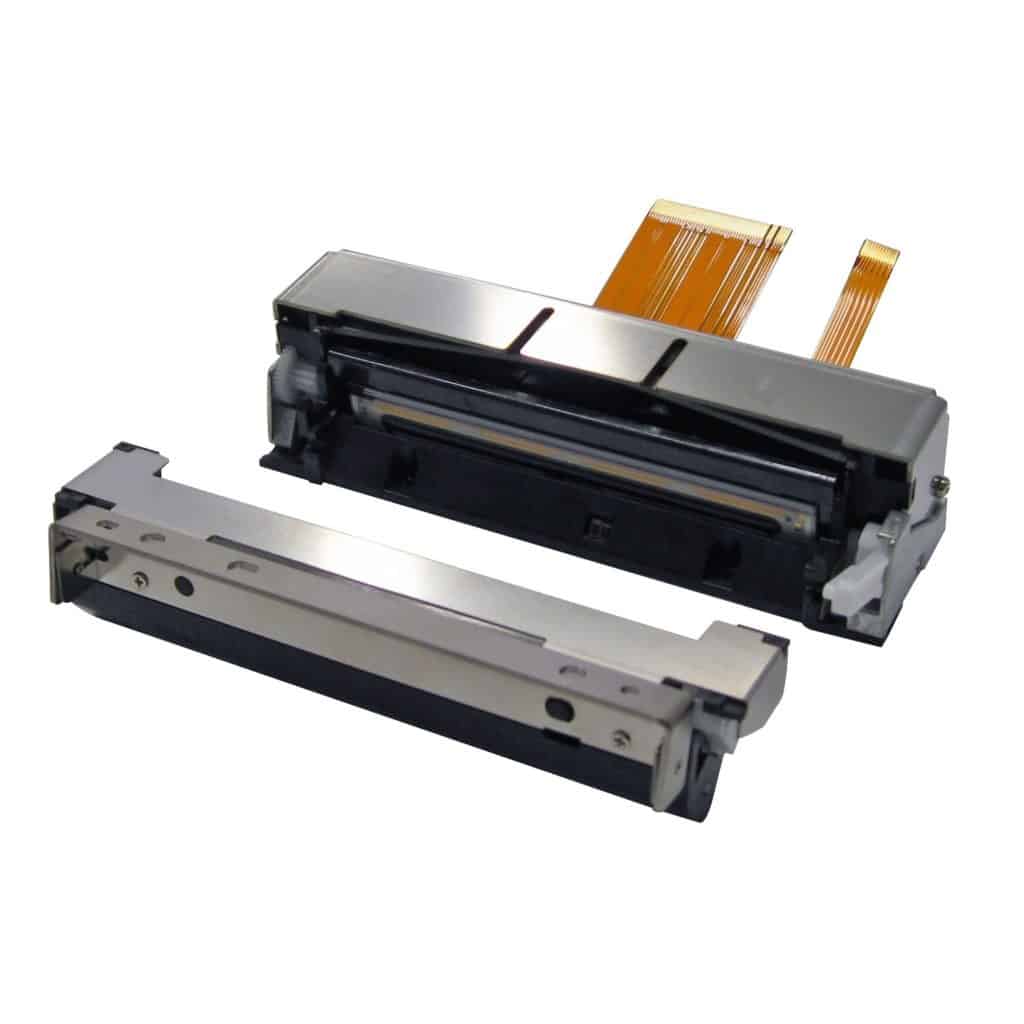

CAPM347 24V Thermal Printer Mechanism

CAPM : 300 mm/s and 2M cuts * 24V range – Paper width 80mm/3″ – EZOP or Automatic Loading

- Max. printing speed: 300mm/s

- Build-in auto paper cutter

- Head open design for easy paper operation

- Heavy duty: 200km, 2mil. cuts

- Wide operating temperature: -20 to 60° C

- Various Drivers

Max. 300mm/s, an extremely high reliability of 200km abrasion resistance and 2 million cuts: the CAPM347 series meets the state of the art in heavy duty thermal printing. The front paper exit structure leaves enough space above the printer for other purposes and prevents e.g. liquids from dropping into the printer. The gears are completely covered to avoid dust entering the printer.

The user friendly mechanism offers models different models: easy paper load, auto paper load as well as models for thick paper applications.

This compact 24V high speed heavy duty thermal printer series supports a wide range of applications in markets such as: Lottery, Ticketing, Parking, Point of Sales and Kiosk.

Serial and USB interface boards are available.

CAPD247/347 24V Thermal Printer Mechanism

24V range mechanism including Auto Cutter – Paper width : 56mm and 80mm – Easy Paper Operation

- 2-inch and 3-inch model available

- Maintaining the compact size including the auto cutter part (height <30mm)

- Printing speed up to 200 mm/s

- Cutting frequency of 30 cuts/minute

- Cutter lifetime of 1.000.000 cuts or more (in specified environment)

- Paper insertion by easy paper operation

- Latch function to secure unchanging pressure between thermal head and platen

The combination of the 24 Volt printer mechanism LTPD247 (horizontal version) plus auto cutter results into this highly reliable, robust, fast and cost oriented printing solution. In addition to the benefits of the LTPD 24 Volt series, the cutter offers a reliability of 1.000.000 cuts minimum ensuring a continuously reliable paper output. With a height of less than 30mm including the auto cutter part this product makes the grade where space is limited.

LTPD247/347 24V Thermal Printer Mechanism

Compact sized and high speed printing, 24V range, Paper width 58mm and 80mm, Easy Paper Operation

- 2- and 3-inch models available

- Compact size (max. height of 30mm)

- High speed printing up to 200 mm/s

- Horizontal and vertical version available

- Easy paper operation paper insertion

- Latch function to secure unchanging pressure between thermal head and platen

- Version with built-in auto cutter available (CAPD Series)

These 24 Volt printer mechanisms are our response to the challenges applications might point during design phases. These mechanisms are very small, fast, robust and reliable. Furthermore we did not forget the orientation to cost targets.

LTPD247/347 are specified for a maximum speed of 200 mm/s. These printers can manage 100 km abrasion resistance and 100 million activation pulse resistance minimum. Considering design flexibility, each model is available as horizontal and vertical type. Paper rolls can be replaced by easy paper operation or automatic paper loading.

CAPD245/345 5V Thermal Printer Mechanism

5V range mechanism inclusively automatic cutter – Easy Paper Operation

- 2-inch and 3-inch model available

- Maintaining the compact size including the auto cutter part (height <30mm)

- High printing speed up to 100 mm/s

- Cutting frequency of 30 cuts/minute

- Easy paper operation paper insertion

- Platen latch function

- Platen position sensor to secure printing quality

The CAPD245/345 combines the printer mechanism LTPD245 (horizontal type) and the highly reliable auto cutter. In addition to the benefits of the LTPD 5 Volt Series, the cutter offers a reliability of 500.000 cuts minimum ensuring a continuously reliable paper output.

LTPD245/345 5V Thermal Printer Mechanism

High performance mechanism / label printing possible * 5V range – Paper width: 58mm and 80mm – Easy Paper Operation

- 2- and 3-inch models available

- Compact Size (max. height of 30 mm)

- High speed printing up to 100 mm/s

- Horizontal and vertical form available

- Easy paper operation and auto loading paper insertion

- Platen latch function

- Platen position sensor to secure printing quality

- Version with built-in auto cutter available (CAPD Series)

LTPD 5 Volt series is the result of following the general market trend of more compactness and high reliability. These mechanisms print fast (up to 100 mm/s) in order to enhance the printing performance of mobile devices. They are highly reliable offering a lifetime of 50 km abrasion and 100 million activation pulse resistance. LTPD 5 Volt series is available in two different forms – horizontal and vertical. Paper insertion can be done by easy paper operation or auto loading. As an additional option two paper sensors support double station printing, which sometimes is required for POS applications.

Case Study: Thermal Print Mechanism and Chip for Temperature Monitoring Units

Our client provides temperature monitoring units for refrigerated vehicles. These compact devices take temperature readings at regular intervals throughout the journey and produce a log of the temperatures alongside the time of each reading. Whether the delivery is a batch of prawn sandwiches, medical vaccines, or cut flowers, this information not only gives the receiver piece-of-mind that the goods have arrived in perfect condition, but also satisfies the legislation that the transport industry has to conform to.

We like to make life easier ….

Our supporting team have all worked in an embedded environment for a number of years, consequently providing knowledge, experience and good advice around all BVM’s products & services when and where you need it. We don’t profess to know everything you need at the time – but we’ll always help in the first instance and get back to you when a little more information is required. If you have a device or application that would benefit from having a print facility, give the team at BVM a call.

You can either Call us directly on +(0) 1489 780 144 and talk to one of the team | E-mail us at sales@bvmltd.co.uk | Or use our quick contact form here.